- Home

- About us

- News

- Products

- Solution

- Innovation

-

- Automotive Coatings

-

- Digital Printing Ink

-

- Printing Inks

-

- Ceramic coating

-

- Stealth aircraft paint

-

- Piezoelectric Ceramics

-

- Ceramic Capacitors

-

- High purity alumina

-

- MLCC

-

- Ceramic pigment

-

- Lithium cathode material

-

- Nano-silica

-

- Carbon Nanotubes

-

- Silicon-carbon anode

-

- Kaolin

-

- LCD Monitor

-

- Nano-titanium dioxide

-

- Nanozirconia

-

- Silicon Nitride Nano

-

- Pesticide suspension

-

- Cell disruption

-

- Medicine

-

- Carotene

-

- Food Industry

-

- Ceramic inkjet ink

-

- Nanopigment

-

- Cosmetic

-

- Nanocatalyst

-

- Chemical materials

-

-

-

-

-

- Automotive Coatings...

-

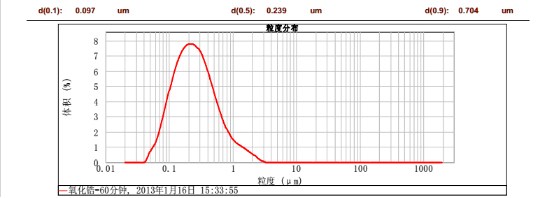

- The results of 60 minutes

-

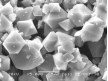

- Finished product particle figure

-

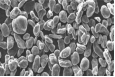

- Nano-colorants particle diameter D50 = 350nm production site

-

- Ceramic membrane production site diameter D50 = 500nm

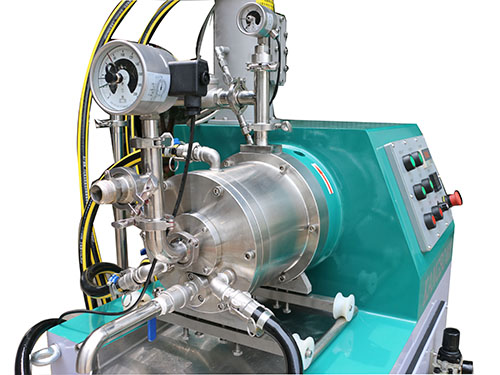

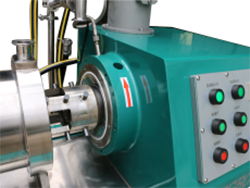

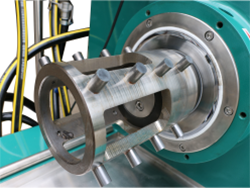

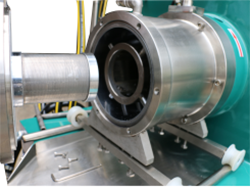

Product descriptionCompro loop stick pin sander is ideal for grinding large number of nanomaterials, represents the most advanced nano-grinding technology, suitable for battery materials, pharmaceutical intermediates, ceramic inkjet, color glaze ceramics, nano-aluminum nitride ultrafine dispersion milling aluminum, silicon carbide, zirconium silicate, nano zirconia, pesticides and other high performance inorganic material; 0.1mm designed to be able to use the grinding media, grinding pin homogeneous rod system, is superior to other milling equipment nanoparticles get the most effective economic methods. By pre-dispersed material into the grinding cylinder barrel, large flow area of the separator, to ensure high efficiency; the strong cooling and temperature control, the result is more accurate.Features BenefitsGrinding get within range of 50nm

Product descriptionCompro loop stick pin sander is ideal for grinding large number of nanomaterials, represents the most advanced nano-grinding technology, suitable for battery materials, pharmaceutical intermediates, ceramic inkjet, color glaze ceramics, nano-aluminum nitride ultrafine dispersion milling aluminum, silicon carbide, zirconium silicate, nano zirconia, pesticides and other high performance inorganic material; 0.1mm designed to be able to use the grinding media, grinding pin homogeneous rod system, is superior to other milling equipment nanoparticles get the most effective economic methods. By pre-dispersed material into the grinding cylinder barrel, large flow area of the separator, to ensure high efficiency; the strong cooling and temperature control, the result is more accurate.Features BenefitsGrinding get within range of 50nm

Smaller grinding chamber and a strong input power, is also a very small diameter grinding media to obtain high strength of the movement, the shear. The average particle size is often less than 50nm.

Use 0.1-0.8mm grinding media

Improved design of stick pin system so small zirconium beads can be high speed, centrifugal separation system, the use of smaller zirconium beads while maintaining the material smooth, high traffic.

Continuous circulation grinding chamber

Straight-type density chamber grinding chamber created, depending on the distance selected mode, the stator and the barrel, in the range of 7.5 to 13 mm, the rotor movement radial movement of the media holding, the product of the shear force is increasing, cylinder forming a continuous loop, within a short time so that the particle size to meet the requirements.

Geometric-shaped design of the grinding chamber, and to ensure uniform particle distribution.

Used in high purity, non-polluting materials

Requirements for non-polluting materials, grinding rod pin can be used zirconium oxide, tungsten carbide material; grinding barrel can use silicon carbide, polyurethane material, the use of a special ceramic material feeder.Configuration parametersStructure type Stick pins Nano sander Weight 480 kg

Types of Horizontal Main motor power 11 kW

Production capacity 3-30 kg/h

Brand KANGBO Applicable materials Water-based, solvent-based nano-dispersion slurry polishing Model CNB-3L

Dimensions 1300*710*1600 m

Feeding capacity 2-6 L/min

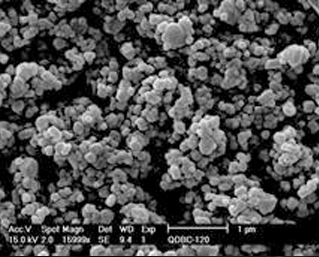

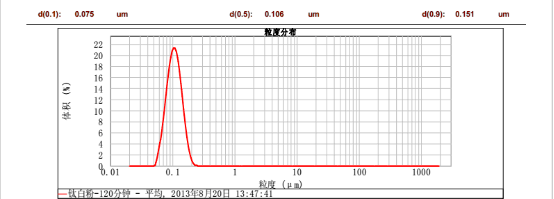

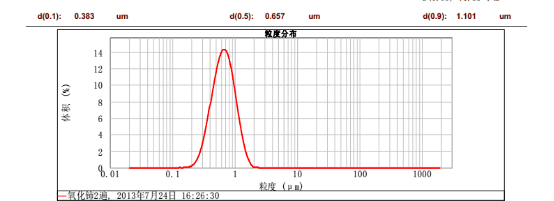

Applications Mass production of nano-materials, battery materials, inkjet ink, ceramic color glaze, nano alumina, nano-zirconia, pharmaceuticals, coatings and inks and other materials Applicable materialsMaterial partCompro CNB-3L nanorods pin sand mill is one of the most extensive abrasive structural applications. For ultra fine powder has obvious advantages, the highlight of the particle size distribution and productivity. For the processing of nanomaterials, grinding bodies inside the material can select different materials. Alternatively silicon nitride, silicon carbide, zirconia, tungsten carbide materials, polyurethane materials. .Grinding data Nano pigment ink particle size after grinding

Nano pigment ink particle size after grinding Lithium iron phosphate material

Lithium iron phosphate material After the zirconium oxide abrasive particlesCNB electronic grade barium titanate nanorods pin sander after fully ground electron microscope FigureCustomer case / application siteRelated RecommendedKANGBO is a collection of dispersed grinding equipment grinding technology and nano-dispersed in one of the overall industry application solution provider. The company is committed to technology research and development and continuous innovation, in a finely dispersed, nano-grinding, slurry filtering, automated filling...KANGBO Provide customers with high-performance nanometer grinding equipment and technology, has developed nano sanding machine, stick pin type three eccentric disc horizontal sanding machine, sanding machine, turbine type nano sand mill industry leading grinding equipment and peripheral accessories application materials...The company's products and solutions for many domestic fine chemicals, including fine ceramics, battery materials, electronics, life pharmaceuticals, coatings, printing inks, inkjet inks, cosmetics and other new materials, through the different product types and the whole diversified services, effective support ...

After the zirconium oxide abrasive particlesCNB electronic grade barium titanate nanorods pin sander after fully ground electron microscope FigureCustomer case / application siteRelated RecommendedKANGBO is a collection of dispersed grinding equipment grinding technology and nano-dispersed in one of the overall industry application solution provider. The company is committed to technology research and development and continuous innovation, in a finely dispersed, nano-grinding, slurry filtering, automated filling...KANGBO Provide customers with high-performance nanometer grinding equipment and technology, has developed nano sanding machine, stick pin type three eccentric disc horizontal sanding machine, sanding machine, turbine type nano sand mill industry leading grinding equipment and peripheral accessories application materials...The company's products and solutions for many domestic fine chemicals, including fine ceramics, battery materials, electronics, life pharmaceuticals, coatings, printing inks, inkjet inks, cosmetics and other new materials, through the different product types and the whole diversified services, effective support ... KANGBO @ Copyright 2016 All rights reserved [Admin]

KANGBO @ Copyright 2016 All rights reserved [Admin]

-

- Innovation

- Solution

- Products

- News