- Home

- About us

- News

- Products

- Solution

- Innovation

-

-

medicine

-

-

Cell disruption

-

-

Pesticide suspension

-

-

MLCC

-

-

Ceramic Capacitors

-

-

High purity alumina

-

-

Piezoelectric Ceramics

-

-

Nano-silica

-

-

Nano-titanium dioxide

-

-

pigment

-

-

Lithium cathode material

-

-

Silicon-carbon anode

-

-

Carbon Nanotubes

-

-

Ceramic diaphragm

-

-

food

-

-

Nano zinc oxide dispersion

-

-

Nano ATO dispersion

-

-

Paste

-

-

Digital printing ink

-

-

-

-

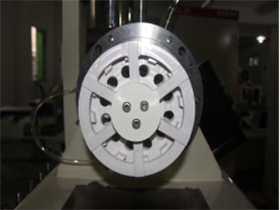

product descriptionCompro turbine sander is used in the field of nano-materials, pharmaceutical intermediates, ultra-fine aluminum oxide, zirconium silicate, ceramic color glaze, battery materials, scientific research such as the production of energy-efficiency grinding machine, suitable for nanomaterials high yield, product particle size distribution after grinding, the minimum can be achieved D50 = 50nm. Turbine sander, high speed products through the turbine, the smooth discharge of the grinding chamber by a feed accelerator. The unique design of the grinding beads and the slurry is formed in the cylinder rotation number of ion flow, thus ensuring gathered a great job in a short time.

product descriptionCompro turbine sander is used in the field of nano-materials, pharmaceutical intermediates, ultra-fine aluminum oxide, zirconium silicate, ceramic color glaze, battery materials, scientific research such as the production of energy-efficiency grinding machine, suitable for nanomaterials high yield, product particle size distribution after grinding, the minimum can be achieved D50 = 50nm. Turbine sander, high speed products through the turbine, the smooth discharge of the grinding chamber by a feed accelerator. The unique design of the grinding beads and the slurry is formed in the cylinder rotation number of ion flow, thus ensuring gathered a great job in a short time.

Features BenefitsHigh flow, high energy grinding

Oversized flow area of the separation system to ensure that the material in the cylinder a short stay, forming a continuous cycle of state, can be a very good qualifying particle exhaust, while the cylinder material quickly into the next cycle of grinding, remain dispersed agreement sex, get the best grinding, the particle size distribution.

Superior grinding capacity, optimum particle size results

The specially designed turbine structure and combine small grinding media can truly superior crushing effect, the particles in the nanometer range.

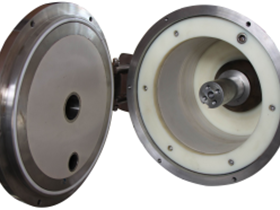

Ideal for non-polluting products

Core components are all zirconia ceramic material, so that the products get a higher purity and zero metal contamination

Intelligent Control System

PLC automatic control, easy operation and parameter display is more accurate

Configuration parametersstructure type High flow nano-turbine sander

weight 470 kg

Types of Horizontal Main motor power 15 kW

Production capacity 2-50 kg/h

Brand KANGBO Applicable materials Water-based, solvent-based nano-dispersion slurry polishing model CNW-6L

Dimensions 1260*700*1500 mm

Feeding capacity 1-4 L/min

Applications Dispersion milling automotive coatings, furniture paint, wood, coil coatings, UV coatings, paint, coatings, inks, pesticides and other liquid slurry

Grinding media particle size

0.1-2.0mm

Applicable materialsMaterial partChoose different materials

Particularly high demand for quality products, high wear-resistant grinding component selection and use, determines the performance of the product, Compro CPG eccentric disk sander using the best wear parts for your application tremendous help .

Alternatively the metal, silicon nitride, zirconia, PU, polymer materials

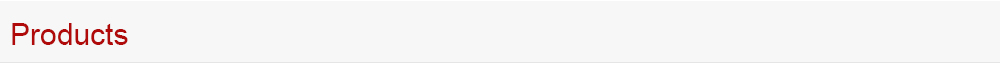

Grinding data After grinding diameter D50 = 0.109um Pharmaceuticals

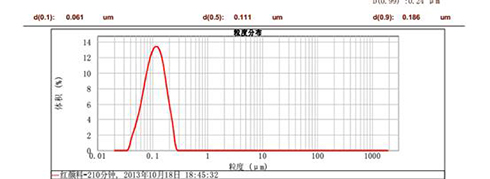

After grinding diameter D50 = 0.109um Pharmaceuticals High purity alumina D50 = 1.072um

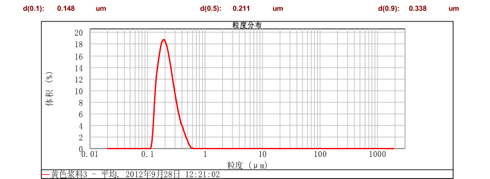

High purity alumina D50 = 1.072um Titanium diboride ceramics D50 = 0.125umRelated RecommendedKANGBO is a collection of dispersed grinding equipment grinding technology and nano-dispersed in one of the overall industry application solution provider. The company is committed to technology research and development and continuous innovation, in a finely dispersed, nano-grinding, slurry filtering, automated filling...KANGBO Provide customers with high-performance nanometer grinding equipment and technology, has developed nano sanding machine, stick pin type three eccentric disc horizontal sanding machine, sanding machine, turbine type nano sand mill industry leading grinding equipment and peripheral accessories application materials...The company's products and solutions for many domestic fine chemicals, including fine ceramics, battery materials, electronics, life pharmaceuticals, coatings, printing inks, inkjet inks, cosmetics and other new materials, through the different product types and the whole diversified services, effective support ...

Titanium diboride ceramics D50 = 0.125umRelated RecommendedKANGBO is a collection of dispersed grinding equipment grinding technology and nano-dispersed in one of the overall industry application solution provider. The company is committed to technology research and development and continuous innovation, in a finely dispersed, nano-grinding, slurry filtering, automated filling...KANGBO Provide customers with high-performance nanometer grinding equipment and technology, has developed nano sanding machine, stick pin type three eccentric disc horizontal sanding machine, sanding machine, turbine type nano sand mill industry leading grinding equipment and peripheral accessories application materials...The company's products and solutions for many domestic fine chemicals, including fine ceramics, battery materials, electronics, life pharmaceuticals, coatings, printing inks, inkjet inks, cosmetics and other new materials, through the different product types and the whole diversified services, effective support ... KANGBO @ Copyright 2016 All rights reserved [Admin]

KANGBO @ Copyright 2016 All rights reserved [Admin]

-

- Innovation

- Solution

- Products

- News