- Home

- About us

- News

- Products

- Solution

- Innovation

-

- Ink

-

- Digital Printing Ink

-

- Ceramic pigment

-

- High purity alumina

-

- MLCC

-

- Ceramic Capacitors

-

- Piezoelectric Ceramics

-

- Lithium cathode materia

-

- Silicon-carbon anode

-

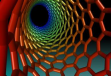

- Carbon Nanotubes

-

- Ceramic diaphragm

-

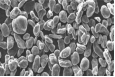

- Nano-silica

-

- Nano-paste

-

- Nano-titanium dioxide

-

- Nanozirconia

-

- LCD Monitor

-

-

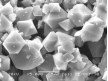

Silicon Nitride Nano

-

-

Kaolin

-

-

Pesticide suspension

-

-

Cell disruption

-

-

Medicine

-

-

Carotene

-

-

Nanocatalyst

-

-

Cosmetic

-

-

Nanopigment

-

-

Talcum powder

-

-

Pearl powder

-

-

Zinc white powder

-

-

Barium sulfate

-

-

-

-

-

-

-

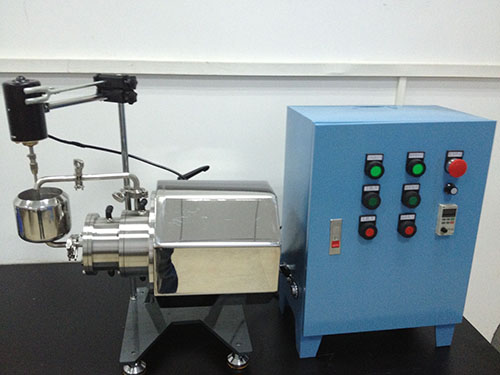

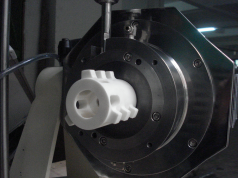

Product descriptionResearch is the ideal tool for the development, development and quality control. Dispersion process, the product is fed into the grinding chamber closed, high speed stirring stick a pin through the blender to form a circular grinding, dispersion, integrated pump pressure system successfully discharged grinding chamber. Due to small size, high cycle efficiency, even if the number of 100ml can be dispersed. In addition, the number of large, by continuously grinding, a very short period of time is completed. To reduce the loss of material, mixing good materials directly to the grinding chamber.

Product descriptionResearch is the ideal tool for the development, development and quality control. Dispersion process, the product is fed into the grinding chamber closed, high speed stirring stick a pin through the blender to form a circular grinding, dispersion, integrated pump pressure system successfully discharged grinding chamber. Due to small size, high cycle efficiency, even if the number of 100ml can be dispersed. In addition, the number of large, by continuously grinding, a very short period of time is completed. To reduce the loss of material, mixing good materials directly to the grinding chamber.

Application:

Experimental research school test

Nanomaterials sample development

Research and testing of ceramic materials, battery materials, digital inkjet, high-performance coatings, pharmaceuticals and other areasFeatures BenefitsFast and cost-effective new models, since the dispersion of precise repeatability.

Fast and reliable experimental shift to the development of production, because of quantitative knowledge required mechanical power input

Production quality control and assurance

Grinding chamber system (stainless steel grinding chamber, nitriding steel grinding rotor) Options: hard metal, ceramic (zirconia), silicon carbide (SiSiC)

Abrasives dynamic gap separation

Mechanical seal sealing manner, constructed for easy installation and system integration, pressure and coolant

Minimize dead

Abrasives may be due to a small amount of dispersion is almost finished product recycling

Millbase yield is very high

Due to the excellent temperature control cooling water system, with a very large surface area

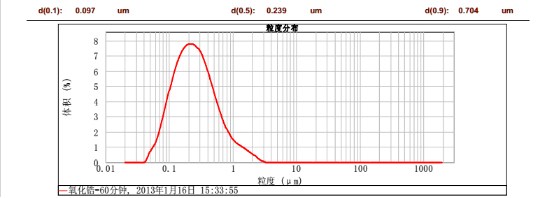

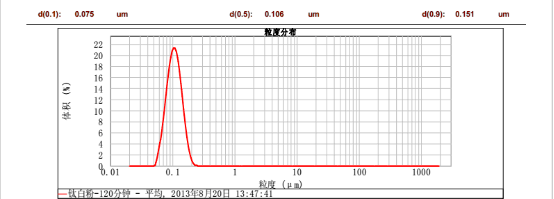

Configuration parametersStructure type Stick pins Nano sander Weight 50 kg Types of R & D type Main motor power 1.5 kW Main motor power 0.2-2 kg/h Brand KANGBO Applicable materials Liquid slurry polishing Model CNB-T0.3L Dimensions 480*400*550 mm Feeding capacity 50-200 g/min Applications Experimental testing a variety of nanomaterials, formulation development, scientific research Applicable materialsMaterial partGrinding data Yellow pigment

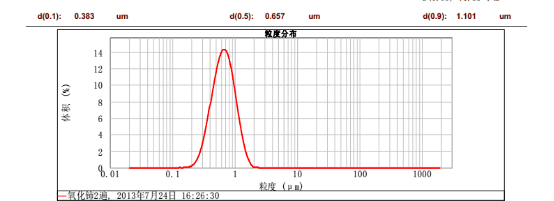

Yellow pigment Electronic Materials

Electronic Materials Printing inkCustomer case / application siteRelated RecommendedKANGBO is a collection of dispersed grinding equipment grinding technology and nano-dispersed in one of the overall industry application solution provider. The company is committed to technology research and development and continuous innovation, in a finely dispersed, nano-grinding, slurry filtering, automated filling...KANGBO Provide customers with high-performance nanometer grinding equipment and technology, has developed nano sanding machine, stick pin type three eccentric disc horizontal sanding machine, sanding machine, turbine type nano sand mill industry leading grinding equipment and peripheral accessories application materials...The company's products and solutions for many domestic fine chemicals, including fine ceramics, battery materials, electronics, life pharmaceuticals, coatings, printing inks, inkjet inks, cosmetics and other new materials, through the different product types and the whole diversified services, effective support ...

Printing inkCustomer case / application siteRelated RecommendedKANGBO is a collection of dispersed grinding equipment grinding technology and nano-dispersed in one of the overall industry application solution provider. The company is committed to technology research and development and continuous innovation, in a finely dispersed, nano-grinding, slurry filtering, automated filling...KANGBO Provide customers with high-performance nanometer grinding equipment and technology, has developed nano sanding machine, stick pin type three eccentric disc horizontal sanding machine, sanding machine, turbine type nano sand mill industry leading grinding equipment and peripheral accessories application materials...The company's products and solutions for many domestic fine chemicals, including fine ceramics, battery materials, electronics, life pharmaceuticals, coatings, printing inks, inkjet inks, cosmetics and other new materials, through the different product types and the whole diversified services, effective support ... KANGBO @ Copyright 2016 All rights reserved [Admin]

KANGBO @ Copyright 2016 All rights reserved [Admin]

-

- Innovation

- Solution

- Products

- News