- Home

- About us

- News

- Products

- Solution

- Innovation

-

-

Nano waterborne paint

-

- Digital Printing Ink

-

- Ceramic pigment

-

- High purity alumina

-

- MLCC

-

- Ceramic Capacitors

-

- Piezoelectric Ceramics

-

- Lithium cathode material

-

- Silicon-carbon

-

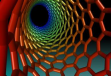

- Carbon Nanotubes

-

- Ceramic diaphragm

-

- Nano-silica

-

- Nano-paste

-

- Nano-titanium dioxide

-

- Nanozirconia

-

- LCD Monitor

-

-

Silicon Nitride Nano

-

-

Kaolin

-

-

Pesticide suspension

-

-

Cell disruption

-

-

Medicine

-

-

Carotene

-

-

Nanocatalyst

-

-

Cosmetic

-

-

Nanopigment

-

-

French chalk

-

-

Pearl powder

-

-

Zinc white powder

-

-

Barium sulfate

-

-

-

-

-

-

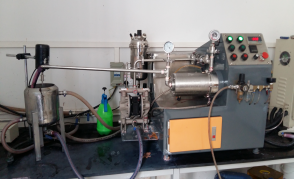

Alumina production field

-

-

Nano pigment production field

-

-

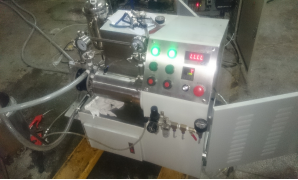

A scientific research units to use the site

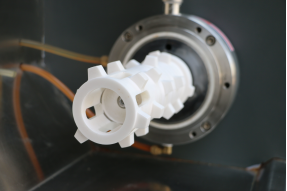

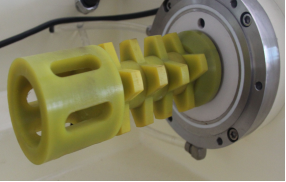

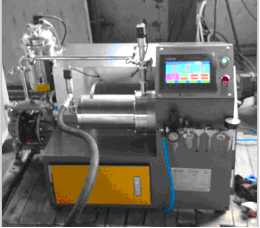

Product introductionCNB - T1L is for product experiment, the ideal of development and quality control tools, small amount of product testing can be performed at the same time; Dispersing process, the product was sent into closed grinding cavity, via the pin mixer to stir bar, the formation of circular grinding, dispersion, by pump pressure discharge grinding cavity smoothly.

Product introductionCNB - T1L is for product experiment, the ideal of development and quality control tools, small amount of product testing can be performed at the same time; Dispersing process, the product was sent into closed grinding cavity, via the pin mixer to stir bar, the formation of circular grinding, dispersion, by pump pressure discharge grinding cavity smoothly.

Application:

Test research school

Nano material sample development

Ceramic materials, battery materials, digital inkjet, high-performance coatings, pharmaceutical and other fields of research and testing

Characteristic advantageImportant features:

Rapid and cost-effective new models, because the dispersed precision repeatability.

Fast and reliable experiment is transferred to the development of production, because the quantitative knowledge of mechanical power input

Production quality control and assurance

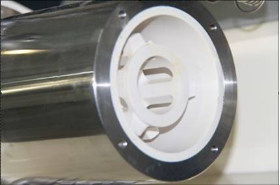

Grinding chamber system (stainless steel mill, steel nitride grinding rotor) options: hard metal, ceramic, zirconia, silicon carbide (SiSiC)

Abrasive mesh clearance separation using special ceramic materials.

Double mechanical seal way, build into easy to install and system integration, pressure and cooling lubricants

Minimize the blind Angle

Abrasive materials a small amount of dispersion is likely due to the almost complete product recycling

Very abrasive production

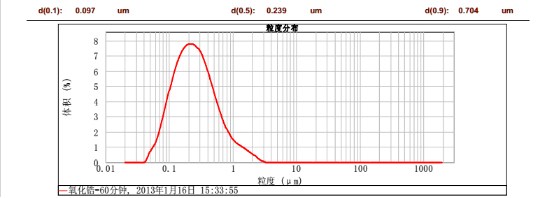

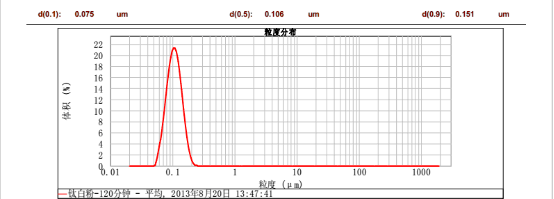

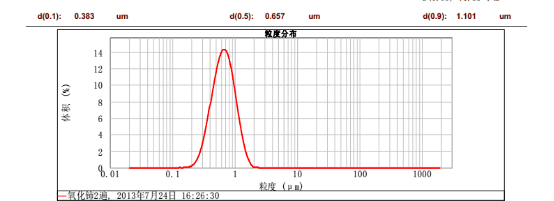

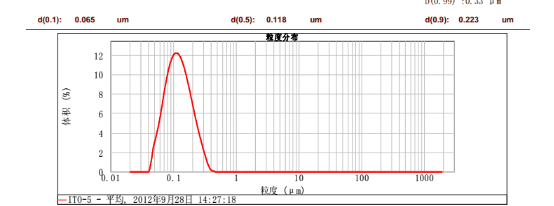

Due to the excellent cooling water temperature control system, has a very large surface areaConfiguration parametersStructure form Pin type nano sanding machine The weight of the 180 kg type Laboratory horizontal Main motor power 3.7 kW Production capacity 0.5-10 kg/h brand KANGBO For the material Water, the solvent liquid pulp grinding model CNB-T1L Overall dimensions 520*460*620 mm Feeding capacity 400-1000 g/min Application field All kinds of nanometer materials lab testing, formulation development, scientific research, such as small sample test For the materialMaterial componentsGrinding data Nano ITO coating

Nano ITO coating zirconia

zirconia Nanometer titanium dioxide

Nanometer titanium dioxide Cerium oxideCustomer case/application fieldRelated RecommendedKANGBO is a collection of dispersed grinding equipment grinding technology and nano-dispersed in one of the overall industry application solution provider. The company is committed to technology research and development and continuous innovation, in a finely dispersed, nano-grinding, slurry filtering, automated filling...KANGBO Provide customers with high-performance nanometer grinding equipment and technology, has developed nano sanding machine, stick pin type three eccentric disc horizontal sanding machine, sanding machine, turbine type nano sand mill industry leading grinding equipment and peripheral accessories application materials...The company's products and solutions for many domestic fine chemicals, including fine ceramics, battery materials, electronics, life pharmaceuticals, coatings, printing inks, inkjet inks, cosmetics and other new materials, through the different product types and the whole diversified services, effective support ...

Cerium oxideCustomer case/application fieldRelated RecommendedKANGBO is a collection of dispersed grinding equipment grinding technology and nano-dispersed in one of the overall industry application solution provider. The company is committed to technology research and development and continuous innovation, in a finely dispersed, nano-grinding, slurry filtering, automated filling...KANGBO Provide customers with high-performance nanometer grinding equipment and technology, has developed nano sanding machine, stick pin type three eccentric disc horizontal sanding machine, sanding machine, turbine type nano sand mill industry leading grinding equipment and peripheral accessories application materials...The company's products and solutions for many domestic fine chemicals, including fine ceramics, battery materials, electronics, life pharmaceuticals, coatings, printing inks, inkjet inks, cosmetics and other new materials, through the different product types and the whole diversified services, effective support ... KANGBO @ Copyright 2016 All rights reserved [Admin]

KANGBO @ Copyright 2016 All rights reserved [Admin]

-

- Innovation

- Solution

- Products

- News